LED Explained

A Light Emitting Diode is a semi-conductive material that produced light via Electroluminescence. This is an optical and electrical phenomenon in which light is emitted from a material when an electrical current or strong electrical field is passed through it.

The invention and development of the high-power white-light LED used in luminaires is rapidly replacing incandescent and fluorescent lighting. The development of LED technology has caused their efficiency and light output to rise exponentially, with a doubling occurring approximately every 36 months since the 1960s.

1. LOW RUNNING COSTS

LEDs are far more efficient at converting electricity into light than alternative light sources. In LEDs, typically 80% - 90% of the electricity is converted into light whereas traditional incandescent lamps only turn around 50% of their electricity into light.

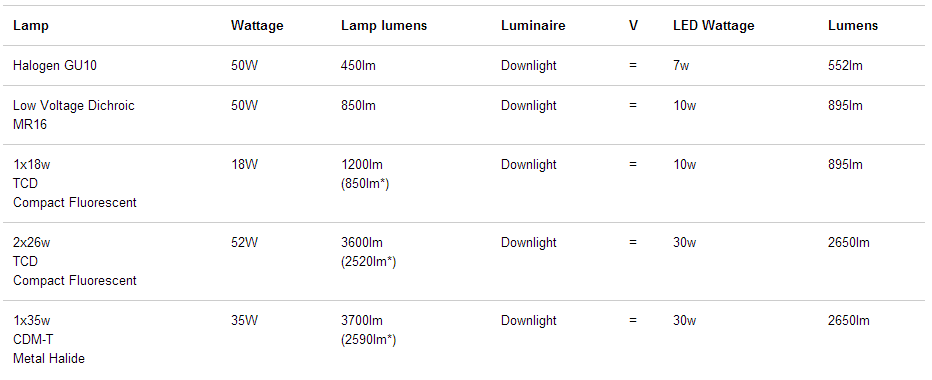

This means you use less power to achieve the same amount of light. An example of how they typically compare is shown below:

*LOR 70%

2. LONG LIFE

Almost all LED luminaire manufacturers quote a life of 50,000 hours for an LED, but they will also normally show L80 after that figure.This relates to the life, so L80 means that at 50,000 hours, you will still have 80% of the light from the LED that you have on day one.

At 12 hours a day 365 days a year, the LED would last around 11.5 years.

To put this in context, a now outlawed Tungsten Candle lamp would give 1000 hour life, a low voltage lamp would typically give 5000 hour life, a Metal halide discharge lamp would give 12,000 hour life and a T5 Fluorescent up to around 20000 hour life.

3. NO HEAT OR UV LIGHT

Incandescent uses 50% of its energy in the infrared/heat range which can't be seen by the eye. In LED's, 100% of the light produced is within our eyesight range of 400-700nm.

4. EARTH FRIENDLY

Unlike fluorescent lights that can contain a lot of different chemicals including mercury, LEDs are free of toxic chemicals and are 100% recyclable.

5. INSTANT LIGHT

Unlike other lamps such as compact fluorescent which take time to warm up to full brightness, LEDs are 100% instantaneous. This makes them perfect for use with switch types such as PIR and occupancy sensors.

6. FLEXIBLE

- Available in different colour temperatures – extremely warm white to daylight (2400k-6000k)

- Available in different sizes.

- Robust - if you drop one it will still work afterwards.

- Work well in different temperatures

- Fully dimmable

When a fitting voltage is applied, electrons are able to recombine within the device, releasing energy in the form of photons. This effect is called electroluminescence, and the colour of the light (corresponding to the energy of the photon) is determined by the energy band gap of the semiconductor.

The LED's are placed on a Wafer, a thin slice of semiconductor material, such as a silicon crystal, used in the fabrication of integrated circuits and other micro devices. The wafer serves as the substrate for microelectronic devices built in and over it. After the preparation of the wafer, it is cut apart into individual dies. Each die is commonly called a chip.

Many LED semiconductor chips are encapsulated or potted in clear or coloured moulded plastic shells. The plastic shell has three purposes:

- Mounting the semiconductor chip in devices is easier.

- The fragile electrical wiring is supported and protected from damage.

- The plastic acts as a refractive intermediary between the high-index semiconductor and low-index open air.

LEDs are diodes that use a p-n junction. The p side is the anode (positive) and the n side is the cathode (negative). Light is emitted when electrons are sent through a material and fall into electron holes causing the electron to fall to a lower energy level which produces energy in the form of a photon. The colour of light (wavelength) depends on the band energy cap forming from the p-n junction.

The History

1907 – London H.J. Round discovers electroluminescence while examining radio waves noticing the phenomenon when using a piece of silicon carbide and a device called 'Cats' Whiskers.'

1920 – St Petersburg Oleg V. Losev studies electroluminescence in radio sets. He publishes a detailed reports but was not known for his work until it resurfaced some 30 years later.

1962 – New York Nick Holonyack (the 'father' of LEDs) develops the first red LED in the visible light spectrum.

1972 – St Louis M. George Crawford creates the first yellow LED.

1972 – New Jersey Herbert Maruska and Jacques Pankove develop the violet LED creating the development of the true blue LED.

1979 – Tokushima Shuji Nakamura develops the first blue LED using gallium nitride (GaN). It is this LED's brilliant blue light which when partially converted by to yellow by means of a phosphor that is the key to the while lights that we use today. He was awarded the Nobel Prize for Physics in 2014 in recognition of this.

There are two main types of LED that we use in modern light fittings:

White light can be formed by mixing differently coloured lights; the most common method is to use red, green, and blue (RGB). Hence the method is called multi-colour white LEDs often referred to as RGB.

Solid-state devices such as LEDs are subject to very limited wear and tear if operated at low currents and at low temperatures. Typical lifetimes quoted are 50,000 to 100,000 hours, but heat and current settings can extend or shorten this time significantly. LED performance is temperature dependent as LED light output rises at lower temperatures, levelling off, depending on type, at around -30°C.

SMD are a newer generation of chips that can be soldered directly onto a printed circuit board therefore requiring less space between them. SMD Chips are usually followed by a number that denotes its size. 35:28 for example meaning a size of 35mm x 28mm. The benefits of this chip are; Low voltage requirements and little generated heat. You'd typically find these on LED Strips, LED retrofit lamps and RGB digital tapes.

COB are the most recent development in chip technology. They are made from multiple diodes (usually more than 9) packaged together on a substrate by epoxy resin or other material and a yellow phosphor covers them over. The result is that when lit, it looks like a single module. The benefits of this type of arrangement are; greater lumen to watt ratio, 30% cheaper build cost, high CRI, high power and intensity. Typical uses are Down Lights, Street Lights and Flood Lights.

【 Go Back 】 | 【 Print 】 | 【 Close this window 】